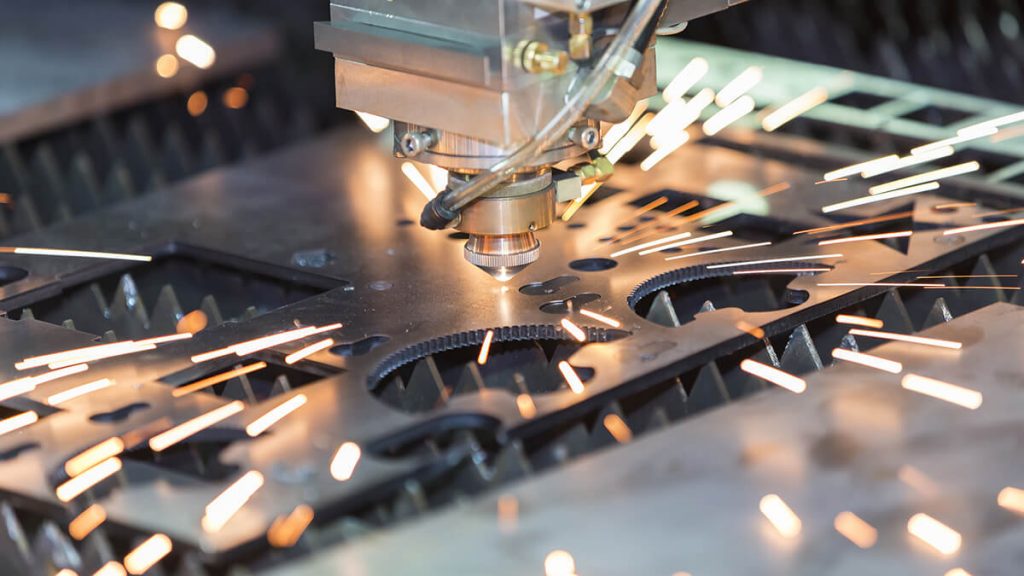

Laserschneiden is a laser cutting and design business located in Germany. At this time, we only b2b offers results, or you must have the lowest amount order we will decide based on the planned scope, which generally starts. Normally, the method uses an active control system to follow a CNC or G-system of the model that is sliced onto the substance. The prompt of lasing equipment forms the laser ray through electrical release or lamps within a closed container. The lasing substance is bigger by being reproduced internally via a part mirror until its power is sufficient to get away as a stream of logical monochromatic light.

Moving material

Moving substance laser cutting equipment features an inactive laser ray and a variable cutting surface to which the substance is attached. The work part is perfunctorily moved across the fixed beam to make the essential cuts. This design allows for a consistent and reliable standoff distance and needs fewer optical gears. Laser cutting is mainly successful in many regions where rapid manufacture is essential. It’s simple to cut correctly in many resources where traditional developed methods are ineffective. The limitations imposed by usual manufacturing development are uninvolved through Laser Cutting, which accesses freedom of plan and quantities.

Uses of laser cutting

Laser cutters have various big benefits when balanced with other built-up techniques. Initially, laser cutters can offer accurate cuts credit to the precise character of laser rays and their skill to only remove substances straight under the beam. Next, laser cutters can slice thin equipment more simply and earlier than normal CNC machines. This is payable to the information that a laser reaper bed uses a gridded form that does not require to hold the work portion down when being sliced. A CNC is required to make various passes when harsh and essential to take the work piece down while also wanting to leave a link between the sheet substance and the piece being cut.

Laser cutting process

Laser cutting is largely a thermal procedure in which an aimed laser beam is used to melt substances in a local area. They b2b offers a completely new form of power which in roll lent itself to utilize in development, medicine, and transportation. Able to high temperature, soften, and even vaporize substance, lasers are seen as the perfect medium for guiding intense but convenient energy. The laser cutting methods provide mechanization with offline CAD/CAM structure and control three-axis flatbed scheme or six-axis machine for 3D laser cutting. Other benefits of laser cutting include reduced risk of worker damage and a quieter process.

Material considerations

Laser cutting is eligible for a range of metal and non-metal supplies and plastic, wood, jewel, glass, and paper. As discussed in the earlier sections, the type of fabric being cut and its goods largely decide the optimal hash mechanism, harsh gas and cutting gas force, and laser appliance to utilize for the laser cutting purpose.

Services

Laserschneiden is a global leader in laser cutting facilities for both designers and makers when it comes to laser cutting. Our equipment is of the main excellence and sourced from reputable manufacturers with reliable supply chains. The wide variety of various engineered supplies that we b2b offers can be used in about any plan possible and the varied range of offered customers demonstrate our facility to provide. Not only are we specialized when it comes to laser cutting, but we also think that trust is the basis of any decent business. As such, we get large care in caring for intellectual property from clients and ensure that all proposals sent are managed with the utmost care.